Aerospace

Advanced CNC Machining for Arizona’s Aerospace Industry

Owens Industries is a top aerospace CNC machine shop serving Arizona, producing precision-machined components. For decades, we have worked with aerospace manufacturers to deliver parts to meet the highest industry standards. From Phoenix to Tucson, Arizona’s aerospace sector counts on our expertise to maintain performance and drive innovation.

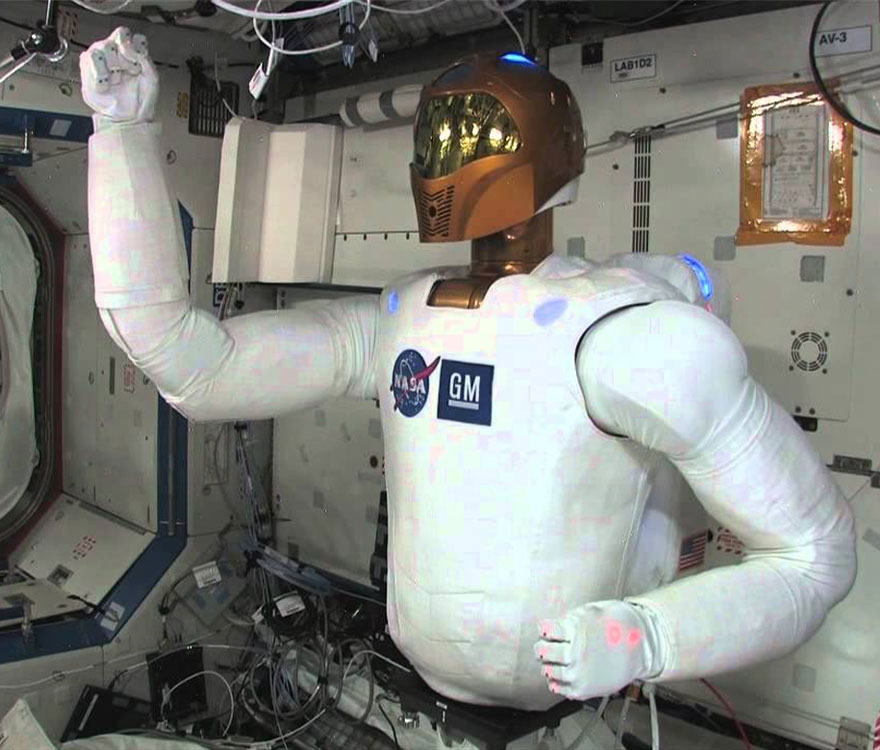

Excellence in Aerospace: Trusted by NASA & General Motors

Owens Industries demonstrates its commitment to precision CNC machining through collaborations with NASA and General Motors on the Robonaut project.

Project Overview: Robonaut Bicep Assembly

As a leading aerospace CNC machine shop, Owens Industries contributed to the Robonaut, a humanoid robot designed to operate in the challenging environment of the moon. This project required high precision and full compliance with NASA’s standards.

Key Challenges

- Aligning components precisely with other robotic parts

- Maintaining functionality in extreme lunar conditions

- Supporting movement for construction and exploration tasks

Our Solution

Using advanced 5-axis CNC machining, our team created the bicep assembly with tight tolerances to meet NASA’s specifications.

Project Outcome

NASA praised the final assembly, leading to the order of two additional units. This collaboration solidified our reputation for delivering precision aerospace CNC components.

At Owens Industries, we apply the same level of quality to every project, consistently providing aerospace parts that meet the highest industry standards.

Capabilities

Comprehensive Aerospace CNC Machining Capabilities for Arizona

Owens Industries is a trusted leader for CNC services in aerospace machining, delivering precision components to Arizona’s aerospace industry.

We provide advanced machining capabilities to meet aerospace manufacturing demands, producing parts with high accuracy, reliability and durability. Our cutting-edge CNC technology allows us to achieve precision exceeding industry standards. Every part is built to perform and last.

Partnering with Owens Industries offers Arizona’s aerospace manufacturers a reliable ally focused on excellence, innovation and timely project completion.

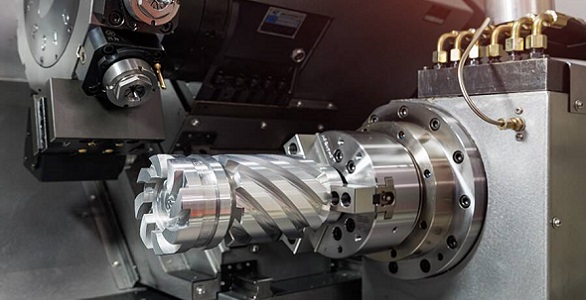

5-Axis CNC Machining Services

Owens Industries offers super precision 5-axis machining for ultra-high precision aerospace components Arizona customers need. We manufacture critical components with high accuracy, including contour rings, hubs, intricate microwave housing parts, and Titan rocket sub-assemblies, using materials like Hastelloy. When precision and reliability matter, Owens Industries delivers.

Wire EDM Services

Wire EDM services from Owens Industries deliver unmatched precision for cutting complex shapes in hard metals commonly used in aerospace applications. This technology is essential for creating intricate components with tight tolerances.

CNC Lathe Turning & Milling Services

Our CNC lathe machining capabilities focus on producing precision aerospace components Arizona companies can count on. We manufacture critical parts such as engine valve pistons from 7075-T651 Aluminum, valve seats from 347 Stainless Steel with tight concentricities and satellite grid clamps from AISI 304 Stainless Steel.

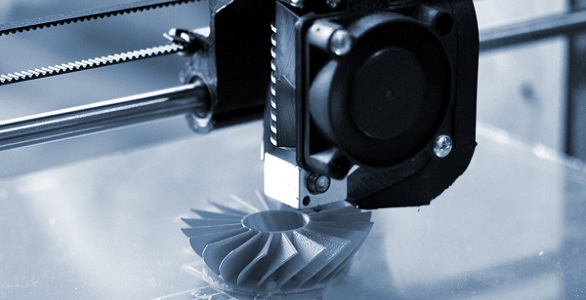

Additive Manufacturing Services

Owens Industries offers cutting-edge additive manufacturing to produce complex parts in the aerospace and defense sectors. Our specialized additive manufacturing capabilities, combined with traditional machining techniques, allow us to create complex geometries, lightweight components and custom parts with precision unmatched by the competition.

Micro Deburring Services

Owens Industries specializes in micro-deburring for aerospace components, guaranteeing precision and a mirror finish on every part. Our skilled professionals utilize advanced technology and by-hand techniques to deliver the accuracy required for critical applications, setting us apart from automated processes other Arizona manufacturers commonly use.

Mill-Turn Machining Services

Our mill-turn machining services combine turning and milling operations in a single setup, ideal for producing complex aerospace parts efficiently. This capability allows us to manufacture a wide range of aerospace components with reduced lead times and improved accuracy.

Materials

High-Quality CNC Materials for Precision Aerospace Parts

We only use high-quality materials to produce precision aerospace components. Each material is chosen to meet specific project requirements for durability and performance. Our commitment to quality guarantees every part meets the stringent standards of the aerospace industry.

An iron and carbon composition with other elements intentionally added, including manganese, chromium, vanadium, nickel or tungsten. Alloy steels are typically divided into two categories: high alloy and low alloy.

Learn More

A high-quality silver metal that’s soft, lightweight, and durable. Aluminum is commonly used for 5-axis CNC machining in military and aerospace applications.

Learn More

A metal alloy made of copper and zinc, made with varying proportions to create a range of brasses with varying properties. Brass has decent strength and electrical conductivity when used in machining parts.

Learn More

An alloy comprised of copper and tin, bronze offers a wide range of properties such as high ductility, hardness, thermal conductivity, strength, and workability. Bronze is often used to manufacture nuts, bolts, threaded parts, bearings, bushings, screws, and more.

Learn More

A metal alloy of carbon and steel, but could also contain nickel, copper or manganese. Carbon steel is commonly used for axles, gears, shafts, rails, pipelines, couplings and more.

Learn More

A common metal used in manufacturing electrical equipment such as wiring and motors. Copper requires specialized processes for manufacturing, meaning copper alloys are more common in machining components.

Learn More

Medium or high carbon steel that has been given heat treatment to temper it, or increase its toughness of the steel. How hard the steel becomes depends on the amount of carbon present in the metal, and it’s typically used to make power shovels, nozzles, surgical instruments, and other manufactured parts.

Learn More

A strong nickel-chromium-iron-molybdenum alloy resistant to corrosion. Hastelloy steel is often used to manufacture contour rings, rings, hubs, flanges, shafts, and other manufactured products.

Learn MoreServing Major Arizona Cities with Aerospace CNC Machining Services

Owens Industries provides precision aerospace CNC machining solutions across Arizona, meeting the rigorous demands of key cities, including:

- Phoenix

- Tucson

- Mesa

- Glendale

- Scottsdale

- Chandler

- Gilbert

- Peoria

- Tempe

- Flagstaff

- Avondale

- Goodyear

- Surprise

- Yuma

- Sierra Vista

Components We Build for the Aerospace Industry

| Part | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|

| Valve Seat | Air Flow Regulator | Mill/Turn | 347 Stainless Steel | Diameters held within 0.0005" Concentricities |

| Control Valve Housing | Aircraft Brake | 4-Axis Milling | 2024-T351 Aluminum | MIL-Spec Ports and Internal Features |

| Check Valve | Brake Fluid Flow Control | Precision Turning | 18-8 Stainless Steel Cond B | 32 Microfinish on all Surfaces |

| Piston | Engine Valve | Conventional CNC Turning | 7075-T651 Aluminum | Maintaining Class 1 Diameter Fit Tolerance |

| Hinge, Convergent Flap | Flap Control | 3-Axis Milling | Inconel 718 | Deep Groove Milling |

| Housing, Aileron | Flap Control | 5-Axis Milling | 15-5PH Cond H1025 | Machining Finned Housing from Solid Billet Stock |

| Battery Core | Safety Equipment | Swiss Screw Machine | 6061-T6 Aluminum | Black Anodized Sleeve |

| Machined Reflector | Wing Lights | 5 Axis Profile Milling | 6061-T6 Aluminum | Milling and Polishing 16 Reflective Pockets |

| Cylinder Assembly | Flow Channel for Booster Rocket | Turning with Ceramic Inserts | A286 Alloy | Deep Drilling Through Interrupted Surfaces |

| Thruster Body | Satellite Propulsion | Precision EDM | 6Al-4v Grade 5 Titanium | EDM Nozzle Micro Taper Vectored Thru-Hole |

| DM Cover | Satellite Component | Mill/Turn | 6061-T651 Aluminum | Turn, Mill, and Drill Flanged Cover |

| Grid Clamp | Satellite Component | CNC Turn | AISI 304 Stainless Steel | Turn 0.044" Thick Ring |