Equipment

Machining Complex Components: with Ultra-Precision German & Swiss Equipment

Owens Industries puts precision and complexity at the core of our operations. With state-of-the-art German and Swiss CNC machining equipment, we deliver exceptional results for industries with non-negotiable accuracy standards. Our cutting-edge machines help us meet the most stringent specifications and exceed industry standards for aerospace, defense, medical, energy and more. Contact Owens Industries today for a quote on ultra-precise CNC machining.

HERMLE 5-Axis CNC Machines

HERMLE machines are renowned for their precision, versatility and advanced technology, making them a cornerstone of Owens Industries’ machining capabilities. Our HERMLE lineup includes the C20, C22 Dynamic, C40 Dynamic and C400, each designed to deliver exceptional accuracy and efficiency for complex 5-axis machining tasks.

Hermle C20

A reliable and efficient 5-axis vertical machining center with an 18,000 RPM spindle ideal for precision milling. Features include a 32-slot tool storage, an internal cooling system and continuous 5-axis capabilities.

Hermle C22 Dynamic

Compact yet powerful, the C22 Dynamic offers high-speed spindles (up to 42,000 RPM) and rapid traverse speeds of 50 m/min, perfect for intricate component production.

Hermle C40 Dynamic

A high-performance machining center with a large working area, traverse speeds of 60 m/min and advanced features like a Renishaw probe for unparalleled precision.

Hermle C400

A state-of-the-art 5-axis machine with a mineral-cast low-vibration bed, the C400 delivers exceptional surface finishes and easily handles complex tasks. HERMLE machines are engineered to meet the demands of high-precision industries, keeping Owens Industries at the forefront of advanced CNC machining.

HERMLE machines are engineered to meet the demands of high-precision industries, keeping Owens Industries at the forefront of advanced CNC machining.

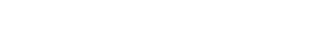

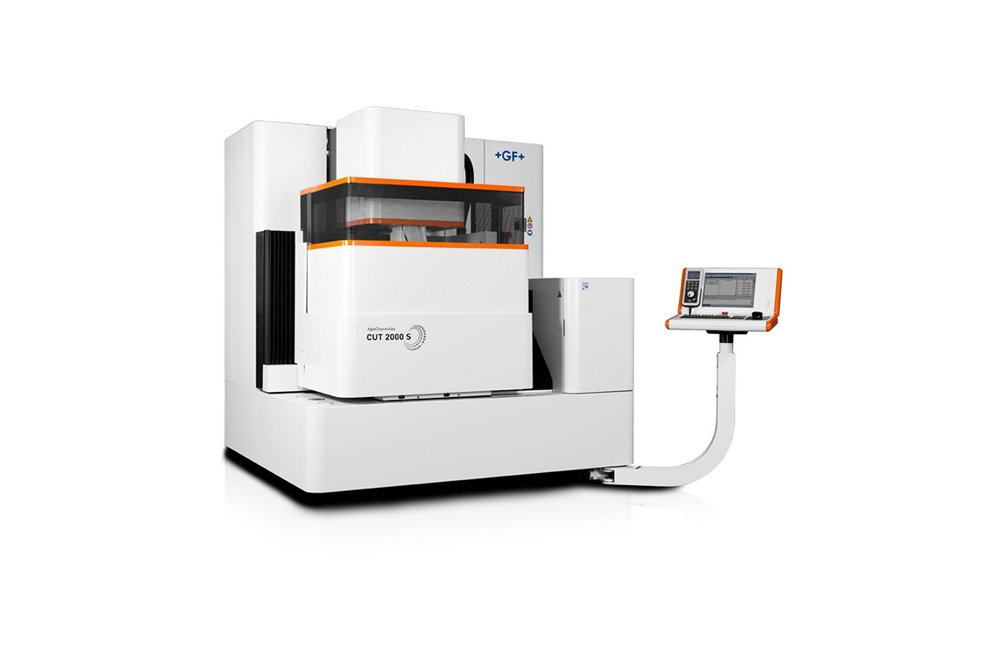

Agie Charmilles Wire EDM Machines

Agie Charmilles machines are renowned for their precision and versatility, making them a cornerstone of Owens Industries’ advanced manufacturing capabilities. Our Agie Charmilles lineup includes the Cut 2000 X w/ Indexer, Cut 2000 S, Cut P 550 Pro and Form E 600, each designed to deliver exceptional accuracy and surface finishes for complex parts.

Cut 2000 X w/ Indexer

A high-precision Wire EDM machine with indexer functionality, ideal for intricate parts in aerospace, medical and tooling industries.

Cut 2000 S

A robust Wire EDM machine offering high-speed cutting and tight tolerances, perfect for complex geometries.

Cut P 550 Pro

A high-performance Wire EDM machine with a large workpiece capacity, designed for precision and efficiency in industries like aerospace and automotive.

Form E 600

This state-of-the-art sinker EDM machine delivers fine surface finishes and advanced die-sinking capabilities for complex geometries.

With features like high-speed cutting, exceptional surface finishes and large workpiece capacities, Agie Charmilles machines empower Owens Industries to meet the demands of high-precision manufacturing across industries.

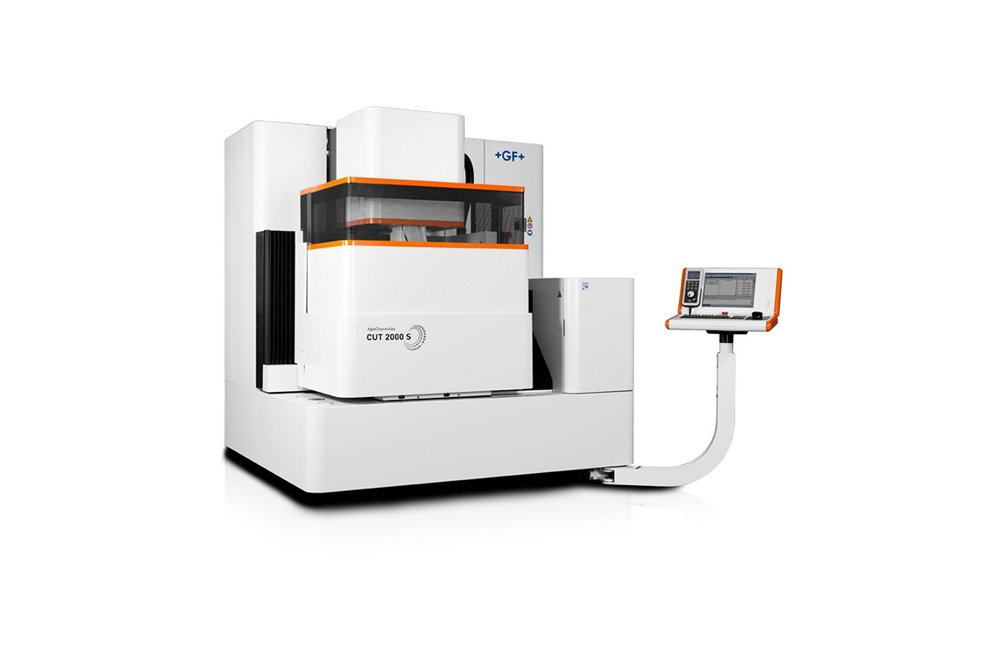

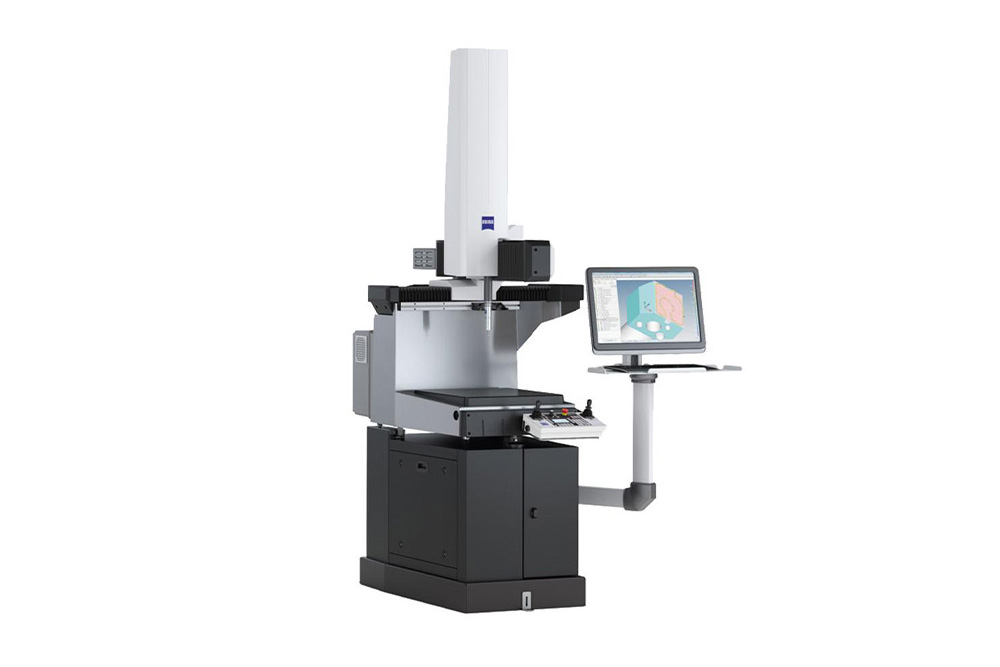

Zeiss Quality Control Inspection Equipment

Zeiss inspection equipment is at the heart of Owens Industries’ commitment to precision and quality. Our Zeiss lineup includes the DuraMax Scanning CMM, O-Inspect 3/2/2 Multi-Sensor CMM, Contura G2 Direkt (2011), Contura (2022) and Contura w/ Line Scan (2022), each designed to deliver unmatched accuracy and reliability in quality control processes.

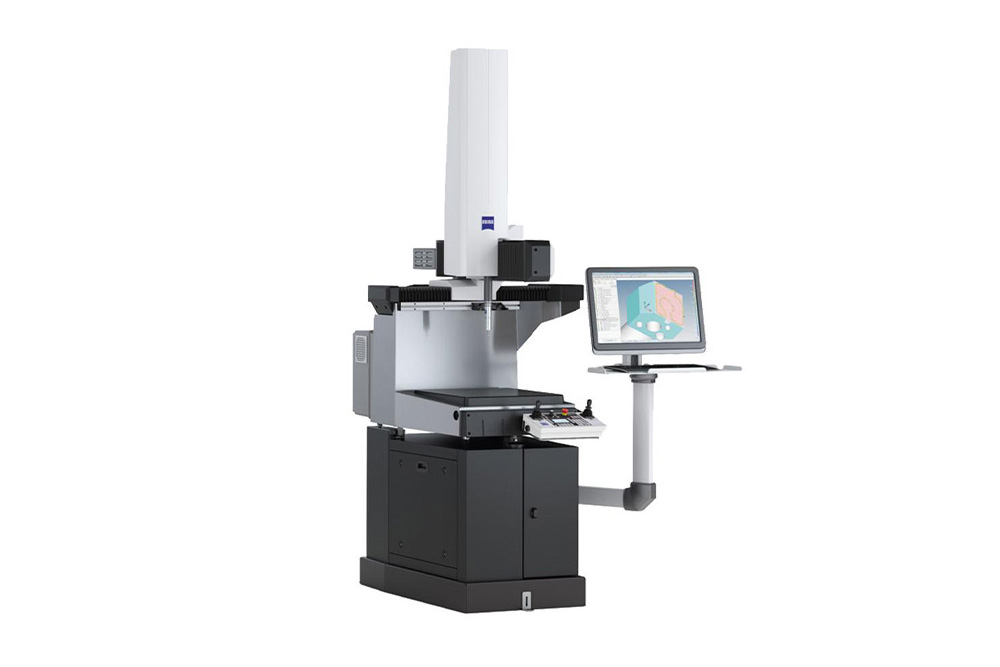

DuraMax Scanning CMM

A high-precision coordinate measuring machine with multi-sensor capabilities, ideal for inspecting complex parts in aerospace, automotive and medical industries.

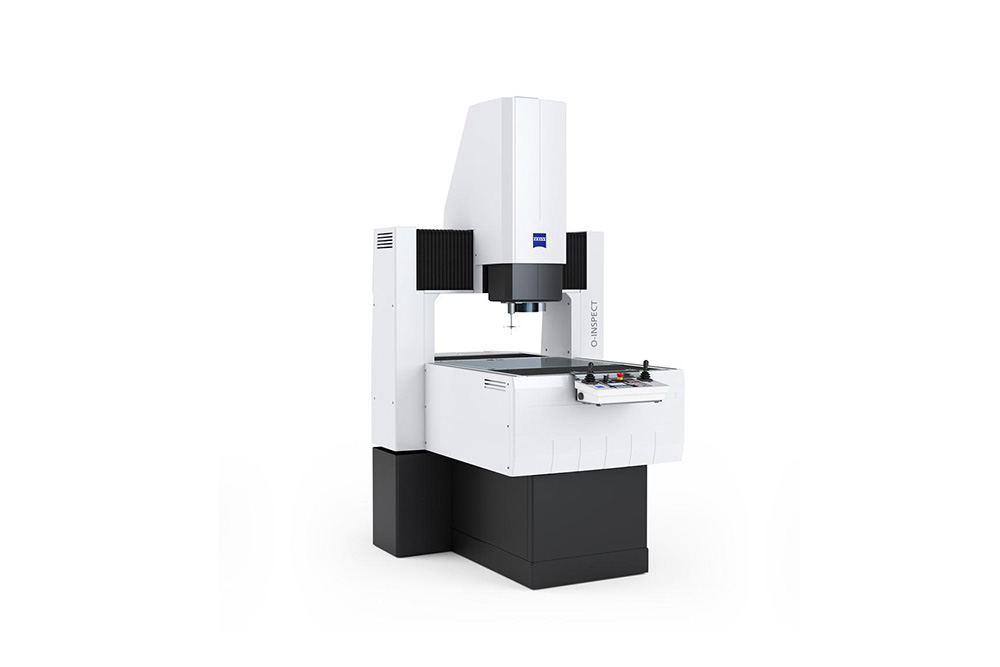

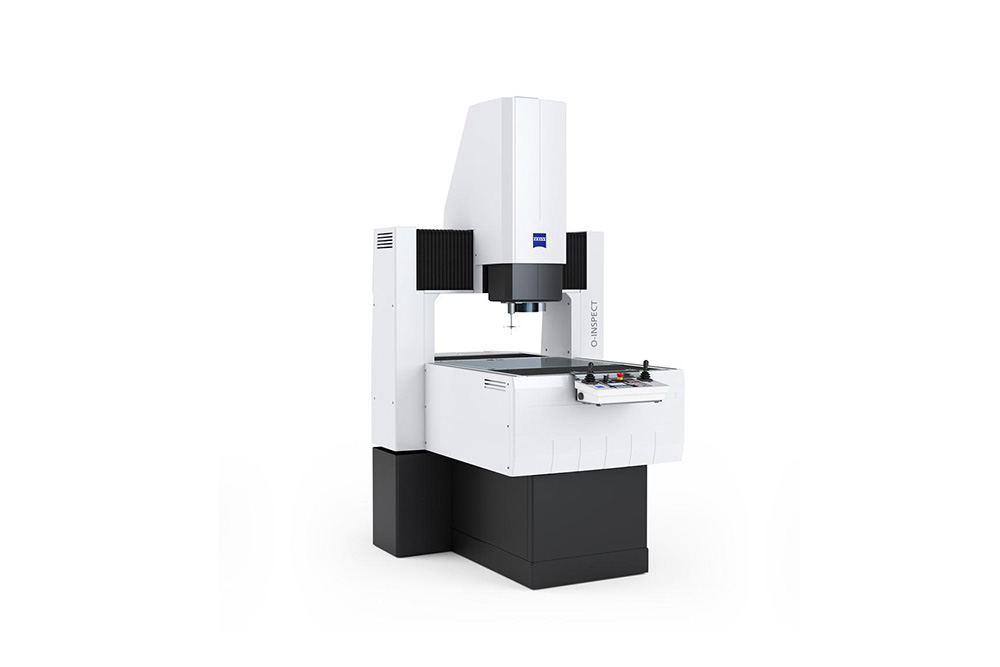

O-Inspect 3/2/2 Multi-Sensor CMM

Combines optical and tactile measurement technologies for versatile and efficient inspection of small, intricate components.

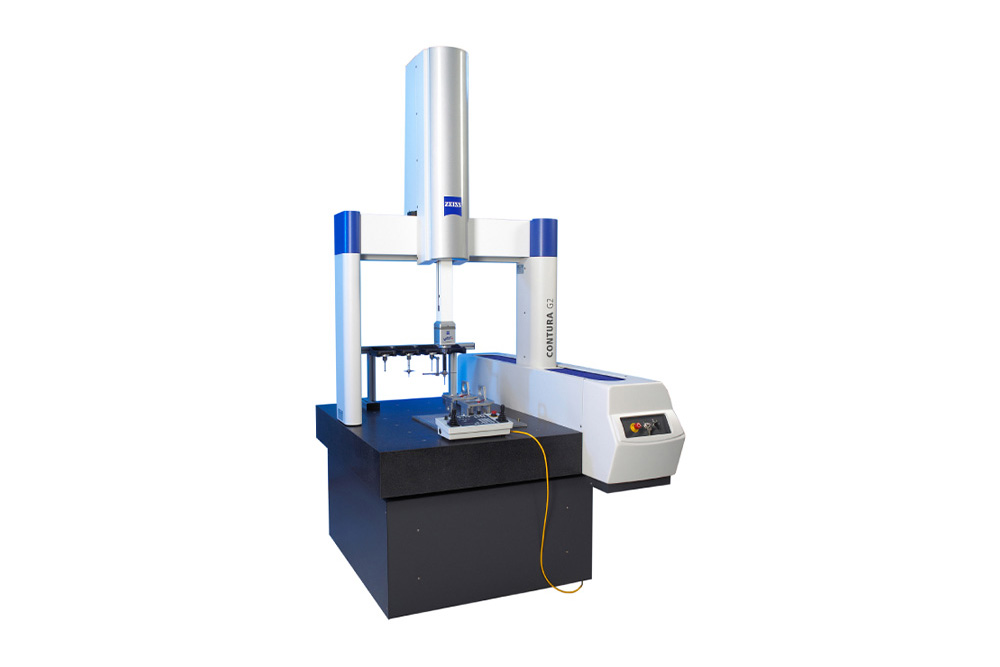

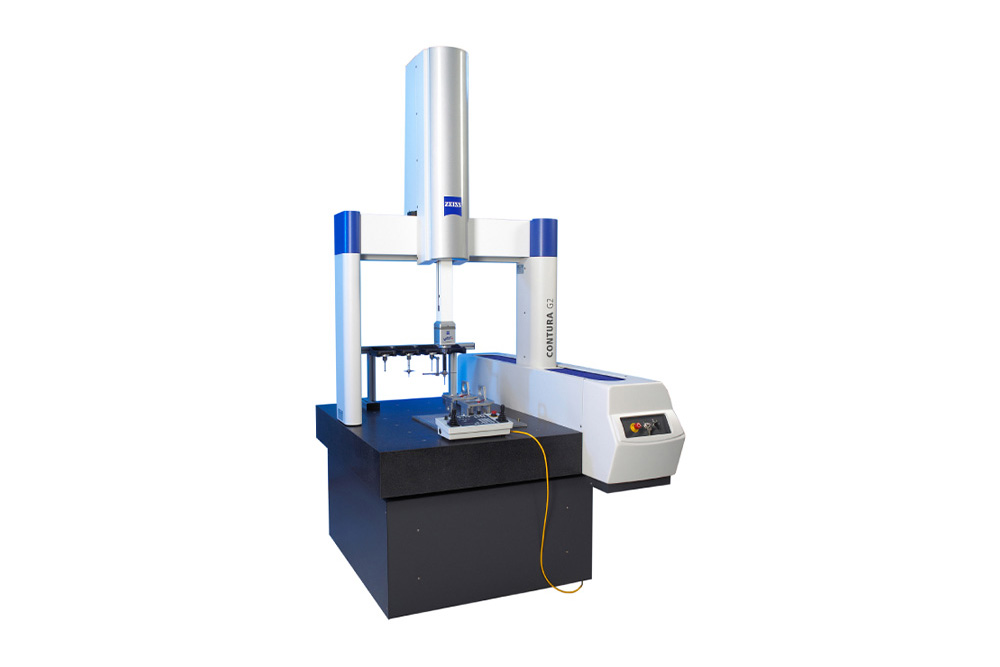

Contura G2 Direkt (2011)

A robust tactile CMM with direct drive technology, the G2 Direkt is perfect for medium to large parts requiring high accuracy.

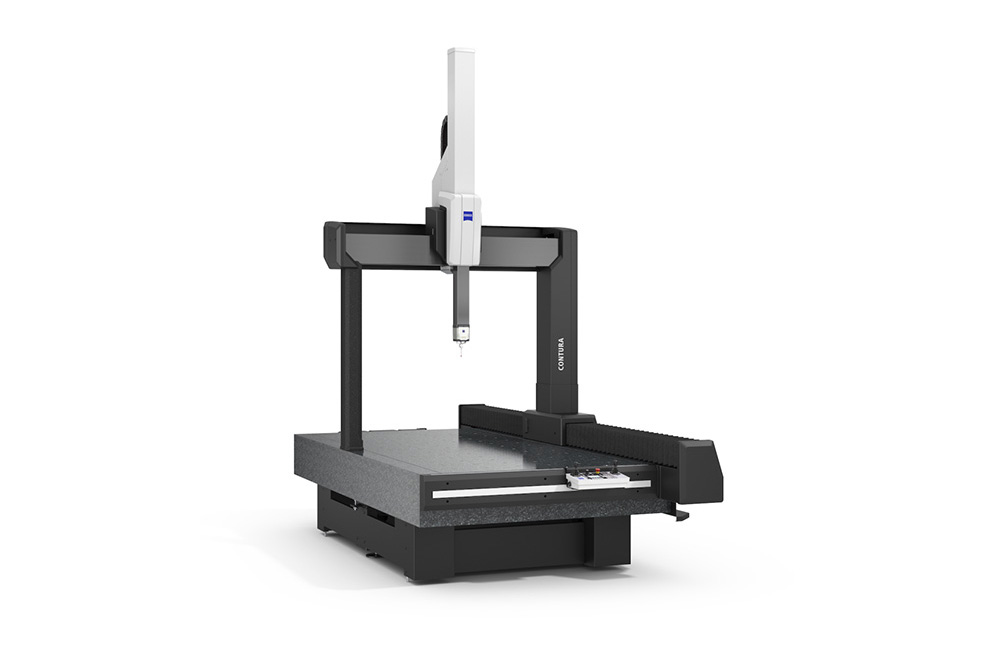

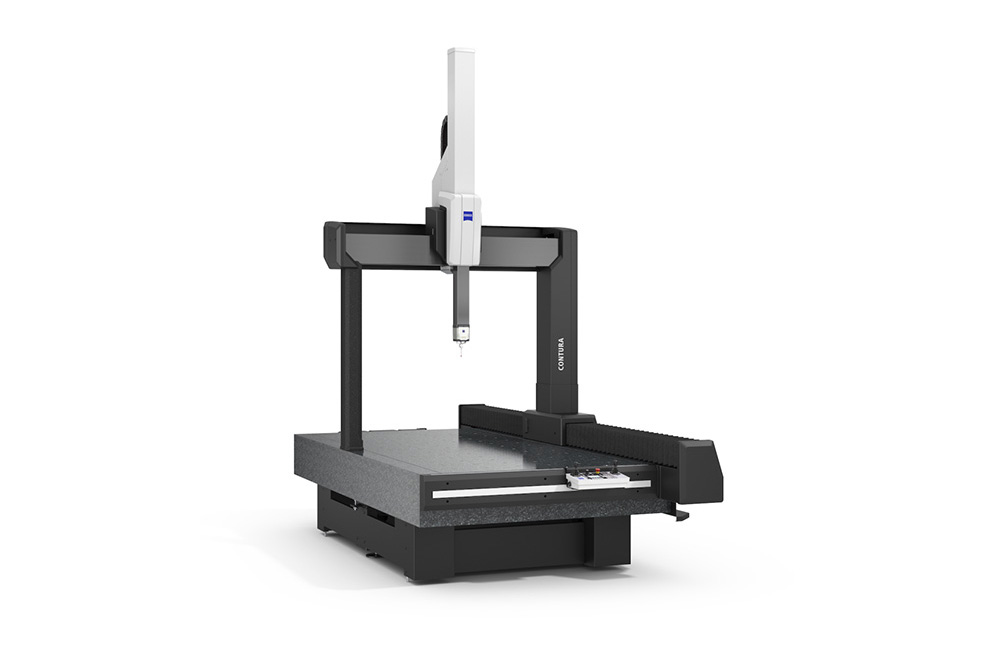

Contura (2022)

This state-of-the-art tactile CMM offers high-speed scanning and exceptional measurement accuracy.

Contura w/ Line Scan (2022)

Integrates tactile and optical line scan sensors for advanced inspection of complex geometries.

Powered by ZEISS CALYPSO and O-INSPECT software, Zeiss machines guarantee Owens Industries maintains unmatched quality standards, delivering precision components for aerospace, automotive and medical manufacturing.

DMG MORI CNC Milling & Lathe Machines

DMG MORI machines are synonymous with precision, versatility and innovation, making them a vital part of Owens Industries’ machining capabilities. Our DMG MORI lineup includes the DMC 60 T Dynamic, NLX 2500, CTX 400, CTX 420 and CTX 310, each engineered to handle complex machining tasks with exceptional accuracy and efficiency.

DMC 60 T Dynamic

A high-performance 5-axis milling machine with a 15,000 RPM spindle and rapid traverse speeds of 1,968.5 ipm, ideal for aerospace, automotive and mold-making industries.

NLX 2500

A versatile turning center combining advanced turning and milling capabilities, perfect for producing complex parts with tight tolerances.

CTX 400

A universal turning center designed for flexibility and efficiency, excelling in aerospace, automotive and energy applications.

CTX 420

A next-generation turning center with a high-speed spindle and multi-functional design, tailored for high-precision machining in demanding industries.

CTX 310

A compact and efficient turning center, ideal for small to medium-sized parts in automotive, medical and electronics manufacturing.

DMG MORI machines empower Owens Industries to deliver precision-engineered components with unmatched quality and reliability, meeting the needs of even the most demanding industries.

Machine Brands

Explore Our Full Range of CNC Machine Brands

Owens Industries partners with the world’s leading CNC machine manufacturers to deliver unmatched precision and versatility. In addition to our HERMLE, Agie Charmilles, Zeiss and DMG MORI machines, we utilize equipment from Okuma and Kitamura to meet the diverse needs of our clients.

Okuma: Renowned for their durability and precision, Okuma CNC milling centers and lathes are ideal for high-volume production and complex machining tasks.

Kitamura: Known for their rigidity and accuracy, Kitamura CNC milling centers excel in producing high-quality components for demanding industries.

Supporting Equipment for Precision Manufacturing

Precision manufacturing requires more than just CNC machines. At Owens Industries, we rely on a suite of supporting equipment to guarantee every component meets the highest standards. From manual lathes to grinders and thread rollers, our additional machines help deliver parts with quality and precision.

- Manual Lathes: Ideal for prototyping and small-batch production

- Manual Bridgeport Mills: Versatile milling machines for a wide range of applications.

- Thread Rollers: Designed for high-precision threading tasks.

- Grinders: Produce flawless surface finishes and tight tolerances.

- Saws: For precise cutting of raw materials.

- Manual Hones: Perfect for finishing and refining internal diameters.

- K.O. Lee Grinder: Delivers exceptional precision for tool and die applications.