Military & Defense

Precision Components Manufactured with Discretion

Owens Industries is the military and defense industry's choice for ultra-precise components. Top organizations trust us as their go-to CNC machine shop. Why? Unmatched precision. Strict confidentiality. Decades of experience.

Our skilled machinists craft complex parts without the specifics of their top-secret applications. We work off your designs, delivering custom-tailored components that meet exact demands with precision and accuracy guaranteed. And we maintain confidentiality through strict agreements for employees, vendors, and visitors.

From concept to creation, Owens ensures your critical operations run flawlessly. Have problem parts or impossible components? In a hurry? Trust our team to get it done.

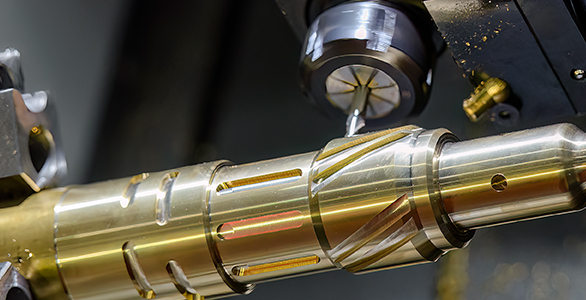

Precision Military Components Made with Our CNC Lathes

When you need precision parts manufactured for military applications, Owens Industries uses CNC machining lathes to build components with the tightest tolerances. Our precision machining professionals can manufacture the best military-grade parts with the highest quality materials – from 5-axis milling to micromachining our technologically-advanced lathes create the most intricate military components at the most affordable cost.

Our machining experts work with the most lightweight and versatile materials, and our CNC experts fabricate military components with the most precise accuracy. CNC lathes are specially made to manufacture the smallest components with precision and ease, meaning your military-grade parts are made to your exact specifications.

Some of the components manufactured with our CNC lathes include:

- Screws

- Spacers

- Artillery Components

- Fighter Aircraft Components

- Missile Components

When you need military-grade parts made with the tightest tolerances, Owens Industries is the way to go. Give us a call today to get more information on our CNC machining services.

Finely Crafted Components Made for Military Aircrafts

The CSTRS team hired Owens Industries to manufacture the guillotines for their naval helicopter. Our reliable CNC machine shop ensured their parts were made with the highest level of quality, accuracy and precision, and their team was 100% satisfied with the work we did for them. Our professional CNC technicians met every one of their needs with our expert machining services, and we can help your company with whatever you need. No matter if you need 5-axis milling or CNC machining, Owens Industries is here to help you.

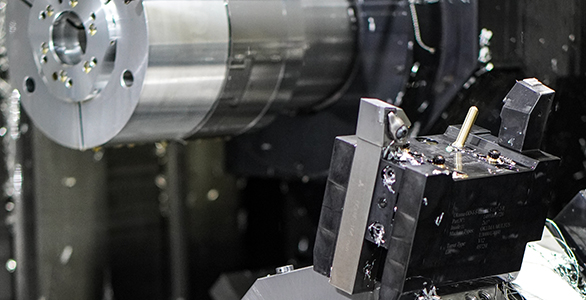

5 Axis Milling for Unmatched Precision and Accuracy of Military Parts

Owens Industries offers 5-axis milling for detailed components, micromachining for accuracy at any size, deburring to ensure flawless application and more. After working with our ultra-precision Machine Shop on your complex component needs, you will partner with Owens for any and all CNC services you require in the future.

Custom components We Make

We have the capability to fabricate custom components with a wide selection of materials, including:

- Stainless Steel

- Inconel

- High Purity Aluminum

- Super Conducting, Very High Purity Copper

- Kovar

- Invar

- Titanium

Our expert machinists develop unique solutions no matter what application you have in mind. If you are looking for a reliable manufacturer capable of performing CNC machine work and EDM with exacting tolerances, Owens Industries will ensure your next operation is a success.

Components We Build for the Military/Defense Industries

Let us be the difference-makers as you begin your military and defense projects. With experience under our belt and industry experts working on our components, we have gained the trust of names like HEICO, Boeing, SNC, Lockheed Martin, Raytheon, AMTEK and Parker.

| Part | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|

| Load Sleeve | Cable Clamp | 5 Axis Profile Milling | Custom 455 Cond H1000 | Saddle Shaped Internal Profile |

| Pawl | Carriage Lock | 4-Axis Milling | SAE 8620 Alloy Steel | Milling Convoluted Profile |

| Blade, Cutter | Cutting Safety Cable | 5-Axis Milling | 17-4Ph Hardened | Keen Damage-Free Cutting Edge |

| Pivot Ball | Military Aircraft | Turning and Spot Welding | 316 Stainless Steel | Welding Carbide Ball to Stainless Steel Stem |

| Paddle | Actuator Arm | 4-Axis Machining | 6061-T6511 Aluminum | Milling 0.020" Thick Webs with 0.002" Flatness |

| Pawl, Leg Lock | Antenna Base | Conventional Milling | 17-4 Ph Cond H900 | Milling Fine Pitched Gripper Teeth |

| Shell Receptacle, 100 Pin | Connector High Temp | 3-Axis Milling | Kovar IAW AMS -I-25011 Class 1 | (100) 0.0445" Diameter Thru Holes |

| Plenum Base | Fuel Flow | Wire EDM | 6LA-4v Titanium per AMS 4928 | Machine 0.010" Thick Tube Wall |

| Actuator, Arm | Night Vision Goggles | EDM Wire | 17-4PH Stainless Steel Cond A | 20 Tooth Ratchet Profile |

| Cutter | Parachute Wire Cutter | 3-Axis Milling | Hardened O1 Tool Steel | Maintaining 0.010" Cutting Edge in V-Groove |

| Read Head | Signal Encoder | 5-Axis Milling and Grinding | 416 Stainless Steel Cond A | Precision Grinding of Flat Surfaces |

| Release Clip | Weapon System Pivot Assembly | 3-Axis Gang Milling | 17-4 ph Casting | Production Run Milling |

Contact our military and defense component manufacturers to discuss your parts today.

View our Success Gallery to see our work!