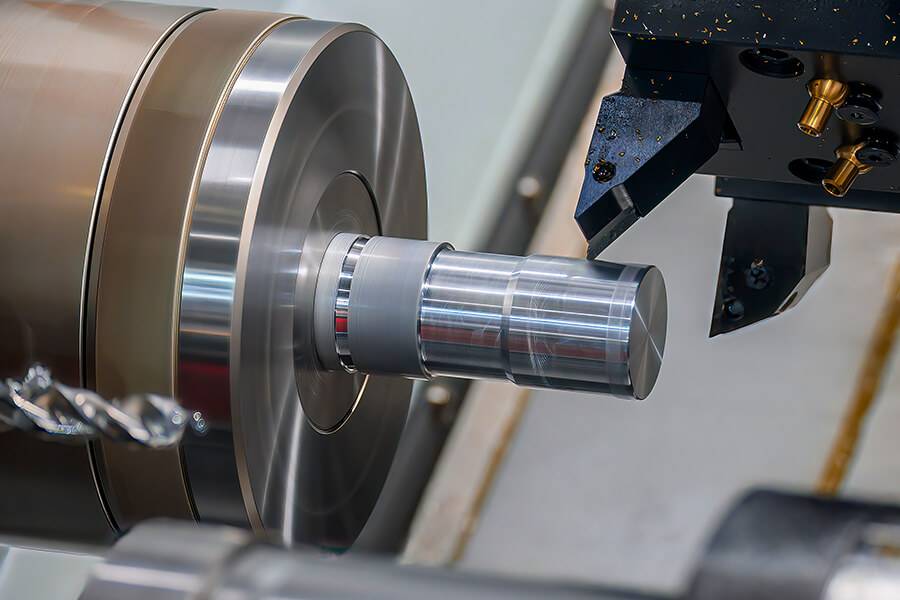

Lathe Machining

Advanced CNC Lathe Machining for the Most Complex Applications

Owens Industries is proud to be a leader in the field of CNC lathe machining and turning. The Owens' team of CNC programmers and machinists are highly trained and experienced, utilizing state-of-the-art horizontal and vertical turning centers to produce complex components. We ensure every lathe machining project meets the highest precision, accuracy, and quality levels. Why settle for anything less?

For problem parts or impossible components, call on the expertise of Owens. We’re committed to consistently delivering top-notch results for our clients.

What is CNC Lathe Machining?

CNC lathe machining and turning is a process in which a computer numerically controlled (CNC) lathe is used to shape and finish a workpiece through the use of rotating cutting tools. In CNC lathe machining and turning, the workpiece is held in place by a chuck and rotated at high speeds while the cutting tools are brought into contact with the workpiece to remove material and create the desired shape

CNC lathe machining and turning is typically used to produce cylindrical parts, such as shafts, pins, and screws, but it can also be used to produce complex shapes and contours. The process is highly precise and allows for the production of high-quality parts with tight tolerances. CNC lathe machining and turning is widely used in a variety of industries, including aerospace, automotive, medical, and more.

Why Choose Owens for CNC Lathe Machining?

Owens Industries excels in CNC Lathe Machining and Turning services, offering unmatched precision with tolerances held to 0.0001 inches. Our automated processes ensure efficient and fast turnaround times, reducing labor costs. We prioritize consistent quality control, delivering identical parts crucial for industries requiring strict tolerances.

Choose Owens for versatile CNC Lathe Machining and Turning, handling diverse components from small intricate parts to large, heavy-duty ones. Our operations prioritize safety, minimizing manual labor to reduce the risk of accidents. With extensive material expertise across 9 industries, Owens ensures reliability and precision in every project with our capabilities in CNC machining.

View our Success Gallery to see our work!

Benefits of CNC Lathe Machining and Turning

There are several benefits to using EDM in manufacturing:

- Enhanced precision CNC lathe machining and turning allows for highly precise machining and finishing of components, with tolerances often held to within 0.0001 inches. This level of precision can be difficult to achieve with traditional machining methods.

- Increased efficiency CNC lathe machining and turning is highly automated, which allows for faster turnaround times and reduced labor costs.

- Improved repeatability Because CNC lathe machining and turning relies on computer-controlled processes, parts produced using these methods are consistently identical. This can be particularly important for industries that require strict tolerances and high levels of quality control.

- Greater versatility CNC lathe machining and turning can be used to produce a wide range of components, from small, complex parts to large, heavy duty components. This versatility makes it an ideal solution for a variety of industries and applications.

- Enhanced safety CNC lathe machining and turning reduces the need for manual labor, which can help to minimize the risk of accidents and injuries on the shop floor. In addition, CNC machines can be programmed to follow specific safety protocols, further enhancing safety on the job.

Examples of Owens’ CNC Lathe Machining and Turning Capabilities

| Part | Application | Industry | Material | Specific Feature |

|---|---|---|---|---|

| Grid Clamp | Satellite Component | Space Research | AISI 304 Stainless Steel | Turn 0.044" Thick Ring |

| Cooling Tube | Natural Gas Meter | Energy Industry | OFE C10100 H04 Hard Copper | Mirror Finish- Polish critical |

| Piston | Engine Valve | Aerospace | 7075-T651 Aluminum | Maintaining Class 1 Diameter Fit Tolerance |

| Barrier | CT Scanner | Medical | 718 Inconel | Used Ceramic Tooling for Turning |

| Static Dog Lock | Transmission Control | Oil & Gas | Lescalloy M50 VIM-VAR | Gear Cutting |

| Chamber | Pneumatic Drill Core | Dental Drill Assembly | 17-4 ph Cond H900 | Honing ID to 8 Micro Finish |

| Inner Race | Replaceable Bearing Track | Oil & Gas | M50 Vim-Var IAW AMS 6491 | 8 Micro Finish on Race Profile |

| Nozzle, Dispensing | Drug Dispensing Nozzle | Medicine Production | 17-4 PH Cond H900 | EDM Wire 2mm Thru-Hole over 8 " Length |

| Solenoid Valve Seat | Hydraulic Piston Seat | Mining | 431 Stainless Steel per BS970 | Ballize Seal Seat to 0.078" Profile |

| Micro-Tip | Instrument Cap | Medical | AISI 316 Stainless Steel | Micro Wire EDM |

| Valve Seat | Air Flow Regulator | Aerospace | 347 Stainless Steel | Diameters held within 0.0005" Concentricities |

| Insulator, Conductivity | Element Isolator | Medical Research | Kel-F PCTFE Plastic | Turn Tapered ID Profiles |

| Barbed Tube Adapter | Fiber Optics Alignment | Microscope assembly | 17-4 ph Cond H900 | Drilling 0.025" Holes |

| Lens Cell | Flow Viewing Port | Natural Gas Industry | 6061-T6 Aluminum | Turn 2.075-32 ID Thread |

| DM Cover | Satellite Component | Space Research | 6061-T651 Aluminum | Turn, Mill, and Drill Flanged Cover |

| Pilot End Cap | Fluid Flow | Engine Manufacturing | 1117 CRS | Milling Radial Ports |

| Nozzle Housing | Circuit Board Manufacturing | Electronics | AISI 316 Stainless Steel | EDM Wire 3 Degree Taper Cone with 8 Micro Finish |

| Control Race | Internal Drive Component | Oil & Gas | M50 Vim-Var IAW AMS 6491 | Grind OD Ball Screw and Broach Internal Spline |

| Mirror Assembly | Gas Meter | Energy | OFHC Copper | High Polish 4 Micro Finish |

| Pivot Ball | Military Aircraft | Defense | 316 Stainless Steel | Welding Carbide Ball to Stainless Steel Stem |

| Cylinder Assembly | Flow Channel for Booster Rocket | Satellite Component | A286 Alloy | Deep Drilling Through Interrupted Surfaces |

| Octopole Housing | Beam Orientation | Research and Development | AISI 304 Stainless Steel | Assembly Alignment of 5 Microns or Less |

| Twin Screw Rotor | Blending | Food Processing | AISI 316/316L | Programmed simultaneous 5 Axis Mill/Turn |

Materials

CNC Lathe Machining Materials Trusted by Owens Industries

Our broad range of material capabilities enable us to meet the specific and varied needs of customers in a variety of industries. Owens Industries has extensive experience manufacturing parts from different materials using CNC lathe machining:

- Brass

- Copper

- Stainless Steel

- Tool Steel

- Alloy Steel

- Aluminum

- Hastelloy

- Inconel

- Invar

- Maraging Steel

- Titanium

Brass

Brass is a metal known for its easy machinability and good electrical conductivity. It is ideal for applications requiring low friction, such as gears, locks, and musical instruments.

| Brass | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C36000 | UNS C36000 | CUZN39PB3 | CuZn39Pb3 |

| C46400 | UNS C46400 | CuZn38Al | Naval Brass |

| C93200 | UNS C93200 | Saems 660 | Bearing Bronze |

| C48500 | UNS C48500 | CuZn39Sn1 | Leaded Muntz Metal |

| C26000 | UNS C26000 | CUZN30 | Cartridge Brass |

| C37700 | UNS C37700 | CUZN40PB2 | Forging Brass |

Copper

Copper is excellent at conducting heat and electricity, making it perfect for electrical uses like busbars and wire connectors. It is easily recognized by its shiny reddish-orange color and is also used in plumbing and roofing.

| Copper | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C11000 | UNS C11000 | Cu-ETP | Electrolytic Tough Pitch (ETP) Copper |

| C10100 | UNS C10100 | OF-OK | Oxygen-Free Electronic (OFE) Copper |

| C10200 | UNS C10200 | OF-Cu | Oxygen-Free (OF) Copper |

| C28000 | UNS C28000 | CuZn40 | Muntz Metal |

| C14500 | UNS C14500 | TeCu | Tellurium Copper |

Stainless Steel

Stainless steel is known for its strength, heat, and corrosion resistance, along with its durability and attractive appearance. These qualities make it suitable for a wide range of uses, including kitchenware, medical instruments, and construction.

| Stainless Steel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 316L | UNS S31603 | X2CrNiMo17-12-2 | Stainless Steel 316L |

| 304 | UNS S30400 | X5CrNi18-10 | Stainless Steel 304 |

| 17-4 PH | UNS S17400 | X5CrNiCuNb16-4 | Stainless Steel 17-4 PH |

| 303 | UNS S30300 | X8CrNiS18-9 | Stainless Steel 303 |

| 420 | UNS S42000 | X20Cr13 | Stainless Steel 420 |

| 440C | UNS S44004 | X105CrMo17 | Stainless Steel 440C |

Tool Steel

Tool steels are hard, stiff, and resistant to abrasion, making them perfect for manufacturing industrial tools. Their robustness is essential for cutting, drilling, and molding applications in various industries.

| Tool Steel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| D2 | UNS T30402 | 1.2379 | X155CrVMo12-1 |

| M2 | UNS T11302 | 1.3343 | HS6-5-2C |

| A2 | UNS T30102 | 1.2363 | X100CrMoV5-1 |

| S7 | UNS T41907 | 1.2355 | 50CrMoV13-15 |

| O1 | UNS T31501 | 1.2510 | 100MnCrW4 |

| H13 | UNS T20813 | 1.2344 | X40Cr |

Alloy Steel

Alloy steels include additional elements beyond carbon, which improve their hardness, toughness, and resistance to fatigue and wear. These steels are widely used in construction, automotive, and machinery due to their enhanced properties.

| Alloy Steel | UNS Designation | DIN Designation | ISO Designation |

|---|---|---|---|

| 4140 | 1.7225 | 708M40 | 42CrMo4 |

| 4340 | 1.6565 | 817M40 | 40NiCrMo6 |

| 8620 | 1.6523 | 805M20 | 20NiCrMo2 |

| 52100 | 1.3505 | 100Cr6 | SUJ2 |

| 4142 | 1.7227 | 708M40T | 41CrMoS4 |

| 6150 | 1.8159 | 735A51 | 50CrV4 |

Aluminum

Aluminum alloys are lightweight and strong, with excellent thermal and electrical conductivity. They are also resistant to corrosion and can be anodized for added protection, making them ideal for aerospace and packaging industries.

| Aluminum Alloy | UNS Designation | DIN Designation | ISO Designation |

|---|---|---|---|

| 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu |

| 6082-T651 | 3.2315 | 64430 | AlSi1MgMn |

| 6060 | 3.3206 | EN AW-6060 | AlMgSi |

| 5052 | EN AW-5052 | 3.3523 | AlMg2,5 |

| 2017A | 3.1325 | 24530 | AlCu4MgSi |

Hastelloy

Hastelloy is a group of nickel alloys known for their high resistance to corrosion, pitting, and stress-corrosion cracking. They are often used in harsh environments like chemical processing and aerospace, where durability is crucial.

| Hastelloy | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C276 | UNS N10276 | 2.4819 | NiMo16Cr15W |

| C22 | UNS N06022 | 2.4602 | NiCr21Mo14W |

| B-2 | UNS N10665 | 2.4617 | NiMo28 |

| X | UNS N06002 | 2.4665 | NiCr22Fe18Mo |

| C2000 | UNS N06200 | 2.4675 | NiCr23Mo16Cu |

| G-30 | UNS N06030 | 2.4603 | NiCr29Mo9Fe |

Inconel

Inconel is a strong, corrosion-resistant nickel alloy, ideal for challenging aerospace applications. It can withstand extreme temperatures and pressures, making it suitable for jet engines and gas turbines.

| Inconel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 718 | UNS N07718 | 2.4668 | NiCr19Fe19Nb5Mo3 |

| 625 | UNS N06625 | 2.4856 | NiCr22Mo9Nb |

| 600 | UNS N06600 | 2.4816 | NiCr15Fe |

| X-750 | UNS N07750 | 2.4669 | NiCr15Fe7TiAl |

| 601 | UNS N06601 | 2.4851 | NiCr23Fe |

| 725 | UNS N07725 | 2.4668 | NiCr19Fe19Nb5Mo3 |

Invar

Invar is a nickel alloy with very low thermal expansion, making it highly stable and perfect for precision applications such as instrumentation and aerostructure molds. It is also used in scientific instruments where dimensional stability is critical.

| Invar | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 36 | UNS K93600 | 1.3912 | FeNi36 |

| 42 | UNS K94200 | 1.3917 | FeNi42 |

| 48 | UNS K94800 | 1.3922 | FeNi48 |

| 32-5 | UNS K94610 | 1.3911 | FeNi32-5 |

| 42-6 | UNS K94620 | 1.3913 | FeNi42-6 |

| 46 | UNS K94630 | 1.3914 | FeNi46 |

Maraging Steel

Maraging steels are ultra-high-strength steels that are easy to machine and weld without causing distortion. They gain their exceptional hardness and toughness from a special heat-treating process, making them suitable for aerospace and tooling applications.

| Maraging Steel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 200 | UNS K93120 | 1.6359 | 20Ni Maraging Steel C200 |

| 250 | UNS K92890 | 1.6358 | 18Ni Maraging Steel C250 |

| 300 | UNS K93120 | 1.6354 | 18Ni Maraging Steel C300 |

| 350 | UNS K93160 | 1.6356 | 18Ni Maraging Steel C350 |

| 400 | UNS K91460 | 1.6352 | Custom 465 Stainless |

| 500 | UNS K92810 | 1.6354 | Custom Age 625 Plus |

Titanium

Titanium is a lightweight metal with excellent strength, low thermal expansion, and high corrosion resistance. Its ability to be sterilized and its biocompatibility make it unique, especially in medical implants and aerospace components.

| Titanium Grade | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 5 (Ti-6Al-4V) | UNS R56400 | 3.7165 | Ti-6Al-4V |

| 2 | UNS R50400 | 3.7035 | CP Titanium |

| 23 (Ti-6Al-4V ELI) | UNS R56401 | 3.7165 | Ti-6Al-4V ELI |

| 9 (Ti-3Al-2.5V) | UNS R56320 | 3.7195 | Ti-3Al-2.5V |

| 7 (Ti-0.2Pd) | UNS R52400 | 3.7235 | Ti-0.2Pd |

| 12 (Ti-0.3Mo-0.8Ni) | UNS R53400 | 3.7105 | Ti-0.3Mo-0.8Ni |

Tolerances

Owens Industries’ Achievable CNC Lathes/Turning Tolerances

For parts that require turning and rotational symmetry, Owens’ CNC lathes and turning services deliver tolerances up to ±0.00025 inches. This level of precision ensures that each turned part consistently meets exact specifications, a necessity in industries such as automotive and aerospace, where even minor deviations can impact functionality and safety. With a maximum part size of 10” diameter by 10” overall length, this service maintains a quick lead time of 10 weeks, allowing clients to receive precise, ready-to-use components that integrate seamlessly into larger assemblies.

| Attribute | Value |

|---|---|

| Maximum Part Size | 10" dia x 10" oal |

| Standard Lead Time | 10 weeks |

| General Tolerances | .0025" |

| Precision Tolerances | .00025" |

| Minimum Feature Size | .060" dia x .050" oal |

| Minimum Surface Finish | 8 |

| Standard Surface Finish | 32 |

*Standard delivery dependent on workloads. Call Owens for current lead times.

Industries

Owens Provides CNC Lathe Machining in Over 9 Industries

With a primary function of forming and shaping different materials, lathes have a wide range of industry applications. Owens Industries serves a variety of industries across the nation and world, taking on parts and production work. Whether you need precision lathe machining services or have complex components requiring lathe machining or turning services, count on Owens to deliver the best possible results.

FAQ

Lathe Machining Frequently Asked

Questions

What is a lathe in machining?

A lathe is a CNC machining tool that rotates a piece of material at high speeds to remove even amounts of the material with a metal cutting tool. Because lathes can easily make symmetrical pieces it is most frequently used to produce cylindrical parts.

What is the difference between milling and lathe machining?

Lathes rotate the material and use a single stationary cutter to remove the material. Milling utilizes a rotating cutter to remove material for a workpiece that remains stationary.

What is the tolerance of a metal lathe?

Computer-controlled metal lathes can achieve tolerances as precise as 0.005".

What are the applications of a metal lathe?

Lathes can be used for facing, contour turning, chamfering, threading, boring, drilling, knurling, and cutoff.

Which industries use lathe-machined parts?

Lathes are versatile machines making them perfect for shaping a wide range of materials for aircraft, military applications, aerospace, medical devices, optical equipment, tools, pharmaceuticals, food, and many more industries.