Materials

High-Quality CNC Machining Materials, Choosing the best material for your component

Determining which CNC material will work best for your component can be difficult. Owens Industries is experienced in machining a wide variety of components from hundreds of different materials. It’s important you pick a material that will work efficiently in your application’s typical environment.

Not sure what material to use? Contact us today.

A heat-treatable, forged material commonly used for aerospace and aircraft component parts.

Learn More

An iron and carbon composition with other elements intentionally added, including manganese, chromium, vanadium, nickel or tungsten. Alloy steels are typically divided into two categories: high alloy and low alloy.

Learn More

A high-quality silver metal that’s soft, lightweight, and durable. Aluminum is commonly used for 5-axis CNC machining in military and aerospace applications.

Learn More

A metal alloy made of copper and zinc, made with varying proportions to create a range of brasses with varying properties. Brass has decent strength and electrical conductivity when used in machining parts.

Learn More

An alloy comprised of copper and tin, bronze offers a wide range of properties such as high ductility, hardness, thermal conductivity, strength, and workability. Bronze is often used to manufacture nuts, bolts, threaded parts, bearings, bushings, screws, and more.

Learn More

A metal alloy of carbon and steel, but could also contain nickel, copper or manganese. Carbon steel is commonly used for axles, gears, shafts, rails, pipelines, couplings and more.

Learn More

A common metal used in manufacturing electrical equipment such as wiring and motors. Copper requires specialized processes for manufacturing, meaning copper alloys are more common in machining components.

Learn More

Medium or high carbon steel that has been given heat treatment to temper it, or increase its toughness of the steel. How hard the steel becomes depends on the amount of carbon present in the metal, and it’s typically used to make power shovels, nozzles, surgical instruments, and other manufactured parts.

Learn More

A strong nickel-chromium-iron-molybdenum alloy resistant to corrosion. Hastelloy steel is often used to manufacture contour rings, rings, hubs, flanges, shafts, and other manufactured products.

Learn More

A nickel-chromium-tungsten-molybdenum alloy that has impressive strength in high temperatures. Haynes also has superb resistance to oxidizing environments up to 1149°C for long periods of time.

Learn More

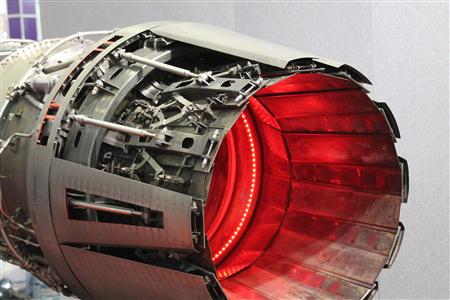

An alloy containing oxidation-corrosion-resistant materials well suited for service in extreme environments. Inconel is often used in gas turbine blades, seals, combustors, thrusters, rotors and other motor shafts.

Learn More

An alloy of iron and nickel is often used in manufacturing office appliances. Invar has the lowest thermal expansion among all metals and alloys in the range from room temperature up to approximately 230°C.

Learn More

A nickel-cobalt ferrous alloy with thermal expansion characteristics. Kovar is often used to manufacture electronic devices such as light bulbs, vacuum tubes and cathode-ray tubes.

Steels that possess qualities of toughness and strength without losing ductility. These steels are iron-nickel alloys with additions of cobalt, titanium, molybdenum and aluminum.

Learn More

A silver-colored metal that is resistant to corrosion but can be deformed into a thin wire without losing its strength. Molybdenum is often used for machining parts necessary in the aerospace industry like turbo pumps, propulsion systems and satellite components.

Learn More

A collection of nickel alloys made up of mostly copper and nickel. Monel is commonly used to manufacture Military and Aerospace machining components such as thrusters, necessary for successful practices.

Learn More

A nickel alloy that has high corrosion resistance and can be used in temperatures up to 315°C. This nickel alloy can be hot-formed into any desired shape and can also be formed cold by any method.

Learn More

Rhenium is commonly used to manufacture parts for high-temperature environments like thrusters and is used in the aerospace industry.

Learn More

A popular industrial alloy used in a wide variety of industries. Stainless steel is used to manufacture handles, medical devices, lab instruments, automotive parts, weld ferrules, and more.

Learn More

Premium stainless steel is commonly used for small and medium-sized inserts and cores.

Learn More

An element alloyed with iron, aluminum, vanadium, and molybdenum. Titanium has high tensile strength and is often used in industries such as aerospace, marine, aircraft, and more.

Learn More

An alloy with a high melting point is often used in aerospace applications. Tungsten has excellent resistance to sticking or welding, and outstanding resistance to metal transfer and electrical erosion.

Learn More

The combination of Vacuum Induction Melting and Vacuum Arc Remelting. This process is used to melt high-grade steels or special metals with electromagnetic induction and remelt consumable electrodes with an arc.

Learn More

A superalloy that is commonly used in high-temperature applications such as gas turbines, thrusters, and hypergolic manifolds. Waspaloy can withstand temperatures of roughly 980°C.

Learn MoreGet high-quality manufactured CNC components made with the best materials from Owens Industries.