Energy

Complex Energy Parts Ultra-Precision Manufactured

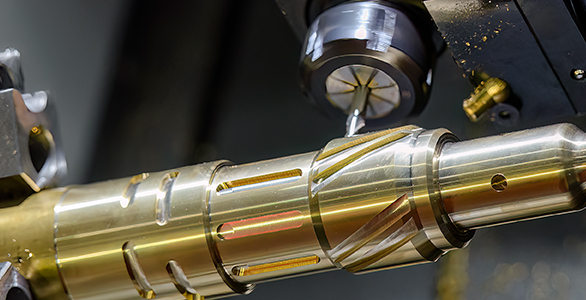

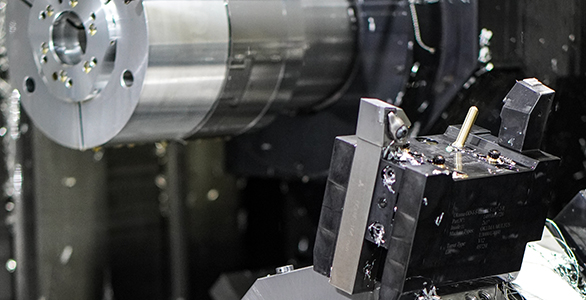

The energy sector is necessary to modern society and is one of the biggest uses of CNC machined components. From wind and solar power to hydropower turbines, components built for the energy industry need to be made with the highest-quality materials and to exact specifications.

Owens Industries’ skilled CNC machinists have worked closely with names like AMTEK, EDWARDS, GE, HALIBURTON, Honeywell and Parker to custom-engineer the highest quality energy components that fit their project's specific needs. Count on us for the best precision parts made with the tightest tolerances. We produce impossible components with ultra-precision that other machinists cannot match.

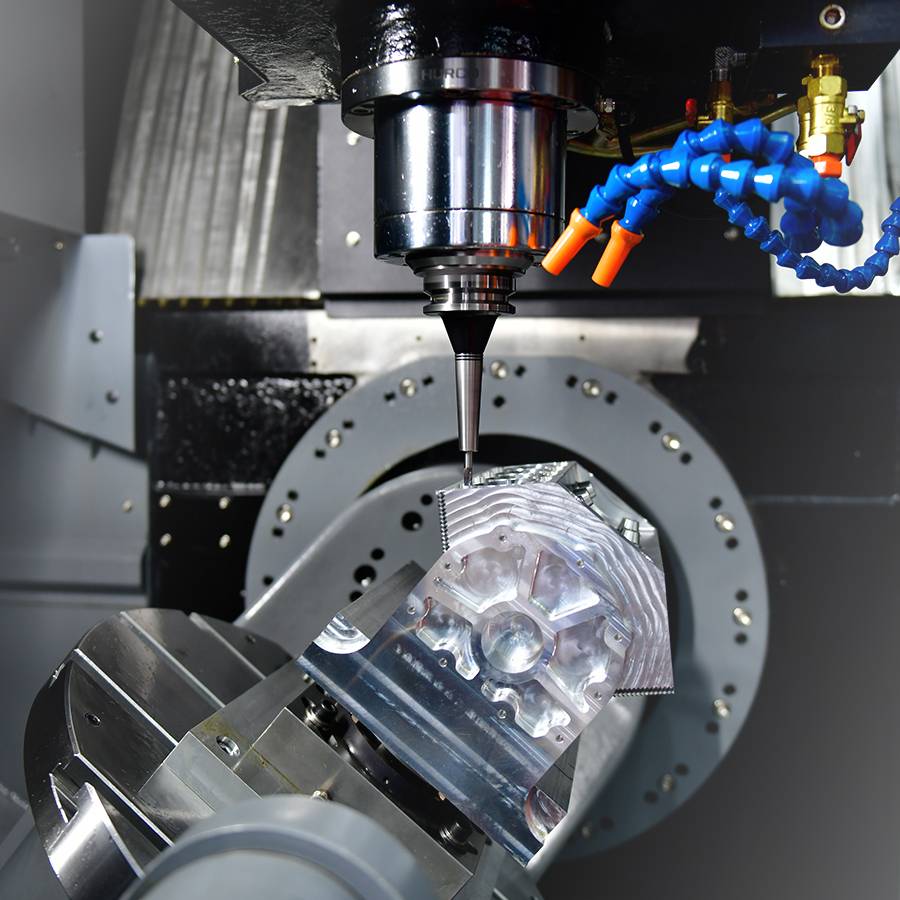

5-Axis Milling for Unmatched Precision and Accuracy

We offer 5-axis milling for detailed components, micromachining for precise components of any size, deburring to ensure a secure seal, and more. Owens Industries has the knowledge, experience, and equipment to create a custom component for nearly any application. We’ll work with you and your designs to assess your situation and create the perfect component tailored to your specific needs.

Owens Industries serves companies nationwide with top-of-the-line CNC services, providing the best precision components for the energy industry. When you’re in need of the most precisely-machined components made by a team of trusted experts, Owens Industries is the company for you.

Materials

Custom CNC Parts Made from High-Quality Materials

Our highly experienced CNC engineers develop all kinds of parts for the energy industry.

- Copper

- Hastelloy

- Titanium

Copper

Copper is excellent at conducting heat and electricity, making it perfect for electrical uses like busbars and wire connectors. It is easily recognized by its shiny reddish-orange color and is also used in plumbing and roofing.

| Copper | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C11000 | UNS C11000 | Cu-ETP | Electrolytic Tough Pitch (ETP) Copper |

| C10100 | UNS C10100 | OF-OK | Oxygen-Free Electronic (OFE) Copper |

| C10200 | UNS C10200 | OF-Cu | Oxygen-Free (OF) Copper |

| C28000 | UNS C28000 | CuZn40 | Muntz Metal |

| C14500 | UNS C14500 | TeCu | Tellurium Copper |

Hastelloy

Hastelloy is a group of nickel alloys known for their high resistance to corrosion, pitting, and stress-corrosion cracking. They are often used in harsh environments like chemical processing and aerospace, where durability is crucial.

| Hastelloy | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C276 | UNS N10276 | 2.4819 | NiMo16Cr15W |

| C22 | UNS N06022 | 2.4602 | NiCr21Mo14W |

| B-2 | UNS N10665 | 2.4617 | NiMo28 |

| X | UNS N06002 | 2.4665 | NiCr22Fe18Mo |

| C2000 | UNS N06200 | 2.4675 | NiCr23Mo16Cu |

| G-30 | UNS N06030 | 2.4603 | NiCr29Mo9Fe |

Titanium

Titanium is a lightweight metal with excellent strength, low thermal expansion, and high corrosion resistance. Its ability to be sterilized and its biocompatibility make it unique, especially in medical implants and aerospace components.

| Titanium Grade | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 5 (Ti-6Al-4V) | UNS R56400 | 3.7165 | Ti-6Al-4V |

| 2 | UNS R50400 | 3.7035 | CP Titanium |

| 23 (Ti-6Al-4V ELI) | UNS R56401 | 3.7165 | Ti-6Al-4V ELI |

| 9 (Ti-3Al-2.5V) | UNS R56320 | 3.7195 | Ti-3Al-2.5V |

| 7 (Ti-0.2Pd) | UNS R52400 | 3.7235 | Ti-0.2Pd |

| 12 (Ti-0.3Mo-0.8Ni) | UNS R53400 | 3.7105 | Ti-0.3Mo-0.8Ni |

Components we build for the Energy Industry

| Part | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|

| Mirror Assembly | Gas Meter | Turning and Polishing | OFHC Copper | High Polish 4 Micro Finish |

| Aperture Plate | Laser Alignment | Fine Wire EDM | Tungsten Nickel Alloy | 250 Micron Thru Holes |

| Joint Seal | Turbine Insert | Conventional Milling | Hastelloy X | Milling thin dog bone profile over 4"-8" length |

| Cooling Tube | Natural Gas Meter | CNC Turning | OFE C10100 H04 Hard Copper | Mirror Finish- Polish critical |

| Inner Diaphragm | Hydraulic Flow | EDM Wire | 6Al-4v Grade 5 Titanium | 4" Diameter Cylinder with 0.008" Thick Wall |

| Prism Base | Laser Focal Component | 5-Axis Milling | Haynes 230 | Drill and Tap 000-120 Threaded Holes |

Contact the CNC machining professionals at Owens for precise, accurate components for the energy industry.

View our Success Gallery to see our work!