Food Manufacturing

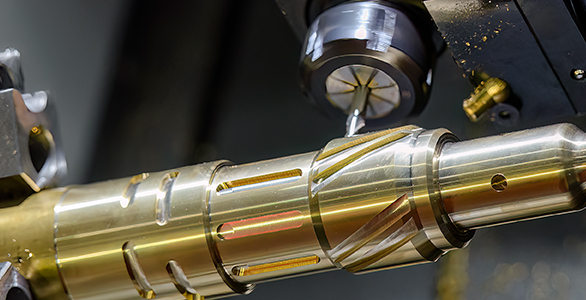

Food Processing Components Made to Extreme Precision

The food manufacturing and processing industry requires the highest quality components and equipment. Over the past few decades, the food industry’s standards for operations have changed drastically due to more regulations around food contaminants, pathogens, and allergens. The Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) require food manufacturing businesses and processing plants to have the highest standards of equipment and components. We have the Current Good Manufacturing Practice (CGMP) in place to review and update these food safety regulations.

Have problem parts or impossible components? In a hurry? Call on the expertise of Owens. We produce parts within extreme tolerances that other machine shops simply can't match.

Expert Machinists at Owens Industries

The expert machinists at Owens Industries know precisely what components you need to keep your food manufacturing and processing company running properly. With our expert machining services and precision lathe work, we guarantee your components will be made with the tightest tolerances and highest-quality materials. The highly-equipped machine shop at Owens Industries is one of the best in the United States, and we will provide you with expert services at the lowest possible prices, like we have done for companies like ABBOTT and EDWARDS.

Give us a call today to get an estimate on your precision parts for the food manufacturing industry.

Materials

Precision Components for Food Manufacturing

CNC machining provides businesses in the food manufacturing and processing industry with the best equipment functioning on a continual basis. Everything from pump shafts and meters to assembly line parts and spray bars, Owens Industries has the capabilities to create the highest quality parts that won’t break or corrode.

- Brass

- Copper

- Stainless Steel

- Hardened Steel

- Carbon Steel

- Alloy Steel

- Aluminum

- Hastelloy

- Inconel

- Titanium

- Bronze

Brass

Brass is a metal known for its easy machinability and good electrical conductivity. It is ideal for applications requiring low friction, such as gears, locks, and musical instruments.

| Brass | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C36000 | UNS C36000 | CUZN39PB3 | CuZn39Pb3 |

| C46400 | UNS C46400 | CuZn38Al | Naval Brass |

| C93200 | UNS C93200 | Saems 660 | Bearing Bronze |

| C48500 | UNS C48500 | CuZn39Sn1 | Leaded Muntz Metal |

| C26000 | UNS C26000 | CUZN30 | Cartridge Brass |

| C37700 | UNS C37700 | CUZN40PB2 | Forging Brass |

Copper

Copper is excellent at conducting heat and electricity, making it perfect for electrical uses like busbars and wire connectors. It is easily recognized by its shiny reddish-orange color and is also used in plumbing and roofing.

| Copper | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C11000 | UNS C11000 | Cu-ETP | Electrolytic Tough Pitch (ETP) Copper |

| C10100 | UNS C10100 | OF-OK | Oxygen-Free Electronic (OFE) Copper |

| C10200 | UNS C10200 | OF-Cu | Oxygen-Free (OF) Copper |

| C28000 | UNS C28000 | CuZn40 | Muntz Metal |

| C14500 | UNS C14500 | TeCu | Tellurium Copper |

Stainless Steel

Stainless steel is known for its strength, heat, and corrosion resistance, along with its durability and attractive appearance. These qualities make it suitable for a wide range of uses, including kitchenware, medical instruments, and construction.

| Stainless Steel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 316L | UNS S31603 | X2CrNiMo17-12-2 | Stainless Steel 316L |

| 304 | UNS S30400 | X5CrNi18-10 | Stainless Steel 304 |

| 17-4 PH | UNS S17400 | X5CrNiCuNb16-4 | Stainless Steel 17-4 PH |

| 303 | UNS S30300 | X8CrNiS18-9 | Stainless Steel 303 |

| 420 | UNS S42000 | X20Cr13 | Stainless Steel 420 |

| 440C | UNS S44004 | X105CrMo17 | Stainless Steel 440C |

Hardened Steel

Medium or high carbon steel that has been given heat treatment to temper it, or increases the toughness of the steel. How hard the steel becomes depends on the amount of carbon present in the metal, and it’s typically used to make power shovels, nozzles, surgical instruments, and other manufactured parts.

Carbon Steel

A metal alloy of carbon and steel, but could also contain nickel, copper, or manganese. Carbon steel is commonly used for axles, gears, shafts, rails, pipelines, couplings, and more.

Alloy Steel

Alloy steels include additional elements beyond carbon, which improve their hardness, toughness, and resistance to fatigue and wear. These steels are widely used in construction, automotive, and machinery due to their enhanced properties.

| Alloy Steel | UNS Designation | DIN Designation | ISO Designation |

|---|---|---|---|

| 4140 | 1.7225 | 708M40 | 42CrMo4 |

| 4340 | 1.6565 | 817M40 | 40NiCrMo6 |

| 8620 | 1.6523 | 805M20 | 20NiCrMo2 |

| 52100 | 1.3505 | 100Cr6 | SUJ2 |

| 4142 | 1.7227 | 708M40T | 41CrMoS4 |

| 6150 | 1.8159 | 735A51 | 50CrV4 |

Aluminum

Aluminum alloys are lightweight and strong, with excellent thermal and electrical conductivity. They are also resistant to corrosion and can be anodized for added protection, making them ideal for aerospace and packaging industries.

| Aluminum Alloy | UNS Designation | DIN Designation | ISO Designation |

|---|---|---|---|

| 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu |

| 6082-T651 | 3.2315 | 64430 | AlSi1MgMn |

| 6060 | 3.3206 | EN AW-6060 | AlMgSi |

| 5052 | EN AW-5052 | 3.3523 | AlMg2,5 |

| 2017A | 3.1325 | 24530 | AlCu4MgSi |

Hastelloy

Hastelloy is a group of nickel alloys known for their high resistance to corrosion, pitting, and stress-corrosion cracking. They are often used in harsh environments like chemical processing and aerospace, where durability is crucial.

| Hastelloy | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C276 | UNS N10276 | 2.4819 | NiMo16Cr15W |

| C22 | UNS N06022 | 2.4602 | NiCr21Mo14W |

| B-2 | UNS N10665 | 2.4617 | NiMo28 |

| X | UNS N06002 | 2.4665 | NiCr22Fe18Mo |

| C2000 | UNS N06200 | 2.4675 | NiCr23Mo16Cu |

| G-30 | UNS N06030 | 2.4603 | NiCr29Mo9Fe |

Inconel

Inconel is a strong, corrosion-resistant nickel alloy, ideal for challenging aerospace applications. It can withstand extreme temperatures and pressures, making it suitable for jet engines and gas turbines.

| Inconel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 718 | UNS N07718 | 2.4668 | NiCr19Fe19Nb5Mo3 |

| 625 | UNS N06625 | 2.4856 | NiCr22Mo9Nb |

| 600 | UNS N06600 | 2.4816 | NiCr15Fe |

| X-750 | UNS N07750 | 2.4669 | NiCr15Fe7TiAl |

| 601 | UNS N06601 | 2.4851 | NiCr23Fe |

| 725 | UNS N07725 | 2.4668 | NiCr19Fe19Nb5Mo3 |

Titanium

Titanium is a lightweight metal with excellent strength, low thermal expansion, and high corrosion resistance. Its ability to be sterilized and its biocompatibility make it unique, especially in medical implants and aerospace components.

| Titanium Grade | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 5 (Ti-6Al-4V) | UNS R56400 | 3.7165 | Ti-6Al-4V |

| 2 | UNS R50400 | 3.7035 | CP Titanium |

| 23 (Ti-6Al-4V ELI) | UNS R56401 | 3.7165 | Ti-6Al-4V ELI |

| 9 (Ti-3Al-2.5V) | UNS R56320 | 3.7195 | Ti-3Al-2.5V |

| 7 (Ti-0.2Pd) | UNS R52400 | 3.7235 | Ti-0.2Pd |

| 12 (Ti-0.3Mo-0.8Ni) | UNS R53400 | 3.7105 | Ti-0.3Mo-0.8Ni |

Bronze

An alloy comprised of copper and tin, it offers a wide range of properties such as high ductility, hardness, thermal conductivity, strength, and workability. Bronze is often used to manufacture nuts, bolts, threaded parts, bearings, bushings, screws, and more.

ISO 9001 Certified Company Made to Help YOUR Business

The CNC engineers at Owens Industries will help you with whatever machining or milling services you need for your company. The components used for the food manufacturing industry can vary in size, shape and density, but the quality will always be the same no matter what parts you need. We can ensure your components will be fully compliant with FDA and USDA regulations, and our services promise to deliver your parts with the tightest tolerances and most affordable prices.

Custom OEM Parts for Less!

If your food manufacturing company is in need of high-quality CNC components for your machinery, call the experts at Owens Industries today! We offer the best 5-axis milling, electrical discharge machining, and more.

Components We Build for the Food Manufacturing Industry

| Part | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|

| Twin Screw Rotor | Blending | Twin Spindle Turning/Milling | AISI 316/316L | Programmed simultaneous 5-Axis Mill/Turn |

Contact the food manufacturing CNC machining experts at Owens Industries today

View our Success Gallery to see our work!