Alloy Steel

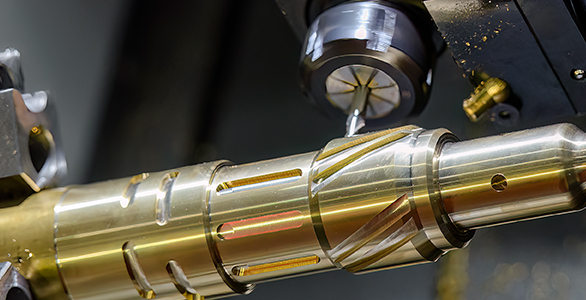

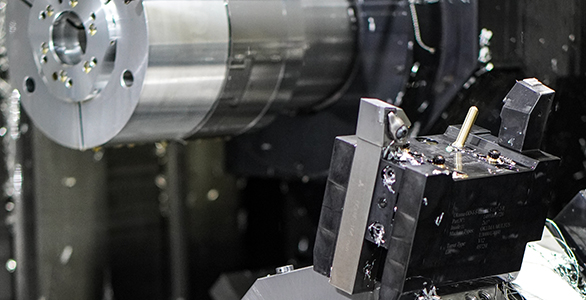

Precision CNC Alloy Steel Machining Services for Complex Components

Owens Industries is a trusted name in providing advanced steel alloy machining services. With CNC technology and state-of-the-art equipment, we are capable of performing complex machining operations for various CNC machining materials including steel alloys. Our advanced machining capabilities include 4-axis and 5-axis milling, swiss machining, and even micromachining. This enables us to create the highest precision parts with the tightest tolerances. We can achieve tolerances as tight as 0.0005".

At Owens Industries, we understand that each project is unique, which is why we offer custom steel alloy machining services tailored to meet specific customer requirements. Our expertise in providing high-quality custom steel alloy parts manufacturing and fabrication services is unmatched. Our commitment to quality assurance and inspection ensures that every precision steel alloy CNC machining service we provide is of the highest standard.

Owens Industries

Alloy Steel Machining Services For Your Industry

Since 1944, designers and engineers have trusted Owens Industries to machine their components and parts from materials such as alloy steel. Owens Industries utilizes advanced CNC technology and machining equipment to offer ultra-precision alloy steel machining services. Our alloy steel machining capabilities enable us to machine alloy steel parts with tight tolerances and complex geometries, making us the go-to partner for various industries. We serve these industries:

Types & Grades of AlloySteel for CNC Machining Services

At Owens Industries, we leverage various grades of alloy steel in our CNC machining services to ensure the perfect match for your project needs. Discover the distinctions and applications of these different alloy steel grades, as they form the backbone of our precision-focused, high-quality services. Make an informed decision and get the best results with us. We work with all types and grades of alloy steel. The following is a list of some of the types of alloy steel we use.

Alloy Steel 1.7131

Alloy Steel 1.7131, also known as 16MnCr5, is a case-hardening steel with excellent wear resistance and strength. It is often used for manufacturing gears, shafts, and other transmission components due to its high surface hardness and toughness. The addition of manganese and chromium provides improved hardenability and wear resistance. This steel is easily machinable in the annealed condition and responds well to heat treatment.

Alloy Steel 4140

Alloy Steel 4140, chromium-molybdenum steel, is known for its high tensile strength, toughness, and fatigue resistance. It is widely used in manufacturing automotive components, axles, and oil and gas industry equipment. This steel can be heat treated to achieve a wide range of mechanical properties and has good machinability in the annealed condition. Its versatility makes it a popular choice for applications requiring both strength and impact resistance.

Alloy Steel 1.7225

Alloy Steel 1.7225, also known as 42CrMo4, is a chromium-molybdenum steel with excellent strength and toughness. It is commonly used in the automotive and aerospace industries for manufacturing high-strength components such as crankshafts, gears, and connecting rods. This alloy steel offers good hardenability and is suitable for various heat treatment processes. Its high fatigue strength makes it ideal for applications where resistance to wear and impact is crucial.

Alloy Steel 4340

Alloy Steel 4340 is a nickel-chromium-molybdenum steel with exceptional strength and toughness. It is commonly used in aerospace and automotive applications, including aircraft landing gear, axles, and high-performance engine components. This steel has excellent hardenability and responds well to heat treatment, making it suitable for various strength and toughness requirements. Its good machinability and resistance to fatigue make it a popular choice for demanding applications.

Alloy Steel 1215

Alloy Steel 1215 is a low-carbon, resulfurized free-machining steel with excellent machinability and surface finish. It is often used for high-speed screw machine parts, bushings, fittings, and other applications where good surface finish and dimensional accuracy are critical. However, due to its low carbon content, it has lower strength and hardenability compared to other alloy steels. It is best suited for applications that do not require high strength or wear resistance.

Alloy Steel 1018

Alloy Steel 1018 is low-carbon steel with good ductility, weldability, and machinability. It is often used for general-purpose applications, such as structural components, shafts, and gears. Although it does not have the high strength or hardenability of other alloy steels, it can be case-hardened to improve its wear resistance. Its excellent formability makes it a popular choice for applications requiring easy fabrication and machining.

Alloy Steel 4130

Alloy Steel 4130, a chromium-molybdenum steel, is known for its high strength, toughness, and resistance to atmospheric corrosion. It is widely used in the aerospace and automotive industries for manufacturing structural components, such as aircraft frames and automotive roll cages. This steel offers good weldability and responds well to heat treatment, making it suitable for various strength requirements. Its combination of strength and ductility makes it an ideal choice for demanding applications.

Alloy Steel 4140 PH

Alloy Steel 4140 PH (pre-hardened) is a version of 4140 alloy steel that has been heat treated to achieve a specific hardness and strength level. This pre-hardened steel offers excellent strength, toughness, and fatigue resistance, making it suitable for applications that require high mechanical properties without additional heat treatment. Common uses include gears, shafts, and heavy-duty machinery components. Its machinability is lower compared to annealed 4140, but it still provides a good balance between strength and machinability for various applications.

Alloy Steel A36

Alloy Steel A36 is a low-carbon structural steel known for its excellent weldability, formability, and machinability. It is widely used in construction, including structural components such as beams, columns, and support plates. Although A36 does not offer the high strength or hardenability of other alloy steels, it provides good ductility and impact resistance. Its versatility and ease of fabrication make it a popular choice for various applications in the construction industry.

A2 Tool Steel

A2 Tool Steel is an air-hardening, medium-alloy, cold-work tool steel with excellent dimensional stability and wear resistance. It is commonly used for making cutting tools, dies, and punches, particularly in applications requiring high wear resistance and moderate toughness. A2 Tool Steel offers good machinability and can be heat treated to achieve various hardness levels and desired mechanical properties. Its combination of wear resistance and dimensional stability makes it ideal for precision tooling applications.

O1 Tool Steel

O1 Tool Steel is an oil-hardening, high-carbon, cold-work tool steel known for its excellent wear resistance, dimensional stability, and toughness. It is commonly used for making cutting tools, dies, and punches in applications where precision and long tool life are critical. O1 Tool Steel offers good machinability and responds well to heat treatment, allowing for a wide range of hardness levels and mechanical properties. Its combination of wear resistance, stability, and toughness makes it a popular choice for high-quality tooling applications.

Owens Industries Precision Machined Alloy Steel Components

Owens Industries has a long storied history of being able to deliver on time and within ultra-precision tolerances. Our precision alloy steel machining services include the machining of various components such as gearboxes, engine blocks, crankshafts, and more. We use advanced machining techniques to achieve tight tolerance and precision in every part we machine. It doesn't matter if you are located near our Wisconsin-based CNC machining facility or not, we serve several different industries all across America in all 50 states.

To see more of our work, please visit our CNC product image gallery and our CNC product video gallery.

Here is an example list of alloy steel components that can be machined:

- Construction components, such as beams, columns, and fasteners

- Transportation components, such as truck and train parts, and marine components

- Energy components, such as oil and gas pipelines and drilling rig components

- Mining equipment components, such as crusher parts and conveyor components

- Agricultural equipment components, such as plow parts and harvester components

- Industrial machinery components, such as gears, shafts, and bearing components

- Power generation components, such as turbines and generators

- Defense components, such as armor plates and weapons components

Interested in utilizing alloy steel for your machined component? Contact Owens Industries today.

Properties of Alloy Steel in CNC Machining

| Alloy Steel | Tensile Strength (MPa) | Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

|---|---|---|---|---|---|---|

| 1.7131 | 800 - 1100 | 640 | 80 | 8 - 14 | 170 - 210 | 7.8 |

| 4140 | 860 - 1040 | 460 - 655 | 80 | 12 - 28 | 180 - 320 | 7.8 |

| 1.7225 | 900 - 1200 | 750 | 80 | 10 - 14 | 200 - 225 | 7.8 |

| 4340 | 1080 - 1280 | 880 | 80 | 12 - 22 | 217 - 302 | 7.85 |

| 1215 | 430 - 530 | 250 - 370 | 75 | 10 - 15 | 120 - 170 | 7.85 |

| 1018 | 420 - 490 | 350 - 420 | 80 | 15 - 20 | 120 - 160 | 7.87 |

| 4130 | 560 - 1040 | 460 - 630 | 80 | 10 - 25 | 180 - 270 | 7.85 |

| 4140 PH | 1000 - 1300 | 850 - 1100 | 80 | 10 - 20 | 270 - 320 | 7.8 |

| A36 | 400 - 550 | 250 | 80 | 20 - 23 | 120 - 160 | 7.85 |

| A2 Tool Steel | 1725 - 2070 | 1400 - 1800 | 78 | 5 - 10 | 207 - 269 | 7.86 |

| O1 Tool Steel | 670 - 2140 | 570 - 1900 | 80 | 5 - 12 | 170 - 230 | 7.87 |

Alloy Steel CNC Services and Capabilities

Happy with our service? Leave us a 5-star review!