5-Axis Machining Services Set Owens Apart from the Competition

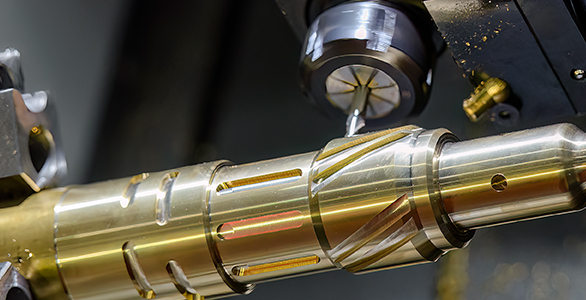

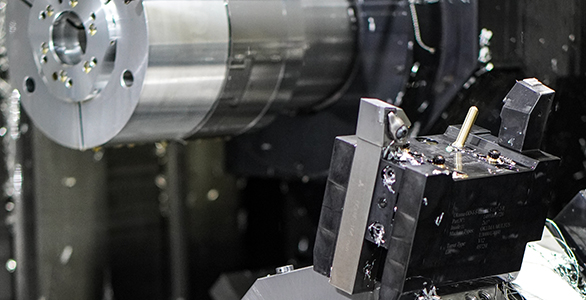

Owens Industries has consistently delivered remarkable results using their 5-axis machining services. If you are seeking impeller or turbine work, you know the complexity of this component’s contours. We seek these challenges, knowing our equipment and 5-axis machine operators have the skills to make impellers with the highest accuracy and precision, no matter the size demands.

Prescription Glasses Moldings

Owens has also created inserts that are used for eyeglass molding – not the frame but the actual mold for the prescription glasses. Though this may sound simple, it is anything but. Visualize the complex curvatures of a bi-focal lens. Now make it a progressive bi-focal; add astigmatism and off-center axes. Many CNC machine shops are not capable of producing the surface tolerance and integrity achieved with the same precision as Owens’ 5-axis machinists. This is just one example of how our team's mathematical skills benefit customers.

Precision Collimators

Another example showcasing our incredible dedication to precision is the production of collimators. Collimators demand ultra-high precision and accuracy to create a high number of holes (depending on its size, a collimator can have 500-1000 holes), each next hole pointing at a different angle than the proceeding hole, with a positional accuracy to be within 5µ to 10µ and an angular accuracy to be within +/- 0.002°. Owens meets these challenges head-on, and successfully achieves the exact specifications these components require—accurately machining each hole so they meet at one focal point.

Ventricular Assist Devices

A third example is the main axial impeller used in the heart pump for VAD—Ventricular Assist Devices. When machining medical devices, precision and accuracy is of the utmost importance - Owens is dedicated to meeting these requirements, delivering precision machined components safe enough to implant within the human body.

Quote from the heart pump manufacturer/customer:

“Your people have achieved, within 6 months, what others took 2 years to make, and your tolerances were better.”

Our machinists perform ultra-precision 5 Axis Precision Machine work with 5 Micron Tolerance and .0005° angular accuracies.

An example of our 5 Axis Precision Machine Work: We produced keratomes for Lasik surgery. A Keratome is used to slice a 165 microns (.006496") thick slice off the cornea of the eye. This slice had to be +/- 5 micron accurate! We produced the entire cutting head system using our 5 Axis Ultra-Precision Machining Centers and our 5 Axis Wire EDM system.

Components we've built using 5-Axis Machining:

| Part | Application | Industry | Material | Specific Feature |

|---|---|---|---|---|

| Machined Reflector | Wing Lights | Aerospace | 6061-T6 Aluminum | Milling and Polishing 16 Reflective Pockets |

| Load Sleeve | Cable Clamp | Defense | Custom 455 Cond H1000 | Saddle Shaped Internal Profile |

| Optics Block | Laser Alignment Tool | Research and Development | 6061-T6 Aluminum | Hole Alignment Tolerance 0.001mm |

| Valve Housing | Titan Rocket | Rocket Engine Component | 6061-T6 Aluminum | 5-Axis Milling of Cylindrical Elbow Housing |

| Housing, Aileron | Flap Control | Aerospace | 15-5PH Cond H1025 | Machining Finned Housing from Solid Billet Stock |

| Support Assembly | Aerospace | Aircraft OEM | 5052-0 and 5052-F Aluminum | Aluminum Tube with Formed Welded Bracket |

| Mixer Head Insert | Spray Nozzle | Automotive | AISI 316 Stainless Steel | Required to mill axial slots at acute angles |

| Blade, Cutter | Cutting Safety Cable | Defense | 17-4Ph Hardened | Keen Damage-Free Cutting Edge |

| Prism Base | Laser Focal Component | Energy Research | Haynes 230 | Drill and Tap 000-120 Threaded Holes |

| Impeller | Fluid Flow | Medical | PEEK | Burr-Free Micro Milling |

| Impeller, Polished | Experimental Heart Pump | Medical Research | 6Al-4v Titanium | Burr Free Polished Impeller Surface |

| Cylinder Block | Gas Flow Manifold | Natural Gas Industry | 6061-T6 Aluminum | Machine 12 Micro Finish Surfaces for Press Fit Bushings |

| Insert | Ball Bearing Flow | Oil & Gas | 17-4 PH Stainless Cond H950 | (6) S-Shaped Pockets on Internal Profile |

| Inlet Cover | Pressure Flow Cover | Oil & Gas | 13CR-L80 80 KISI MYS | Milled Cage Features |

| Radial Bearing Housing | Shaft Control Unit | Oil & Gas | 17-4 ph Cond H950 | Deep Feature 5-Axis Milling |

| Bearing Housing | Shaft Coupling Device | Oil & Gas | 13CR-L80 80 KSI MYS | Intricate Internal Ports |

| Ball Lock | Transmission Control | Oil & Gas | AISI 4330 V Mod 115 Min KSI Yield | Milling Eccentric Lobe |

| Equalizing Flapper | Valve Cover | Oil & Gas | 718 Inconel NACE MR0175 120 KSI MYS | Milled Saddle-Shaped Profile |

| Flapper Mount | Valve Head | Oil & Gas | Inconel 925 105 Min KSI Yield | Milling Saddle Profile |

| Soft Seat | Well Head Seal | Oil & Gas | 30% Carbon Filled Teflon | Saddle shaped stepped profile seal ring |

| Soft Seat Retaining Ring | Well Head Seal Retainer | Oil & Gas | 13CR-L80 | Milling Saddle Profile |

| Spiral Groove Bearing | Transmission | Research and Development | 660 Bronze | Mill Radial 0.010" Deep Chevrons on Part OD |

| Read Head | Signal Encoder | Military | 416 Stainless Steel Cond A | Precision Grinding of Flat Surfaces |

Happy with our service? Leave us a 5-star review!