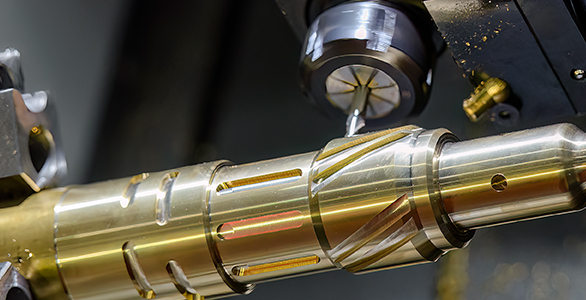

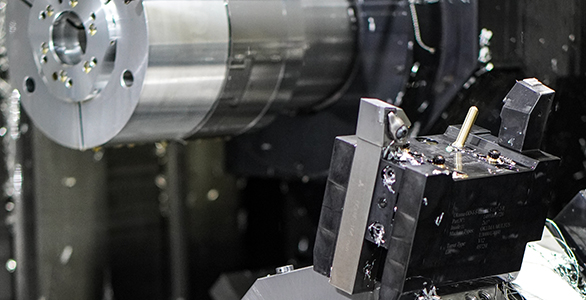

Micromachining, 5-Axis Milling, Wire EDM, and More

Springfield is a thriving city in the heart of Massachusetts, in the vicinity of both Boston and New York City which makes it well suited for distribution and industry. Healthcare is a large part of Springfield’s economy, with the Baystate Health Center providing 12,000 jobs for people in the Springfield area.

Owens Industries’ CNC machines achieve the tightest tolerances and most precise accuracies for components across a variety of industries in Springfield, MA. From Wire EDM to 5 Axis Milling and more, our capabilities exceed customer expectations and consistently deliver repeatable accuracy “normal” machine shops cannot provide.

| |

Surgical Device Parts Machined to the Highest Precision

Owens Industries is the right choice for CNC machining of medical parts for the Springfield medical industry, including:

- Surgical scissors – an essential instrument in virtually every medical procedure, when they’re not used to get into skin they are used to cut sutures. Surgical scissors are available in a number of shapes and sizes to fit the need of a wide range of applications – they are particularly small when used in eye surgeries.

- Cannulas – medical products like IV cannulas are in high demand because they’re used in virtually every medical center across the world. Like many surgical instruments, they are available in multiple sizes, similar to needle gauges. We use state-of-the-art equipment like multi-axis milling and wire EDM to produce high precision cannulas that are safe and effective. The hollow metal tube and sharp, angled point of an IV cannula can be produced with exacting accuracies.

- Biopsy tubes – what is being biopsied determines the type of biopsy needle used during the procedure. Since not all biopsies are the same, there is no one size fits all needle for the task. We understand that safety, accuracy, and cost are all important factors when manufacturing medical tools.

- Saw guides for bone surgery – helps orthopedic surgeons make the cleanest cuts possible, and protects against cutting too far into bone while sawing. Orthopedic procedures require the highest precision machined tools to produce the highest precision results.

Whether you need a prototype machined for an industry-changing implant, manufacturing services of small, intricate components for surgical instruments, or have a design that other machine shops cannot accomplish with precise accuracy, Owens welcomes your challenges. Our trained professionals will work alongside you from start to finish, accomplishing even the most impossible machining goals.

Get a quote for high-quality medical machined components from the experts at Owens Industries.

Have problem parts or impossible components? In a hurry? Call on the expertise of Owens. Complex parts with tight deadlines are our specialty.

Get high-quality manufactured CNC components made with the best materials from Owens Industries.